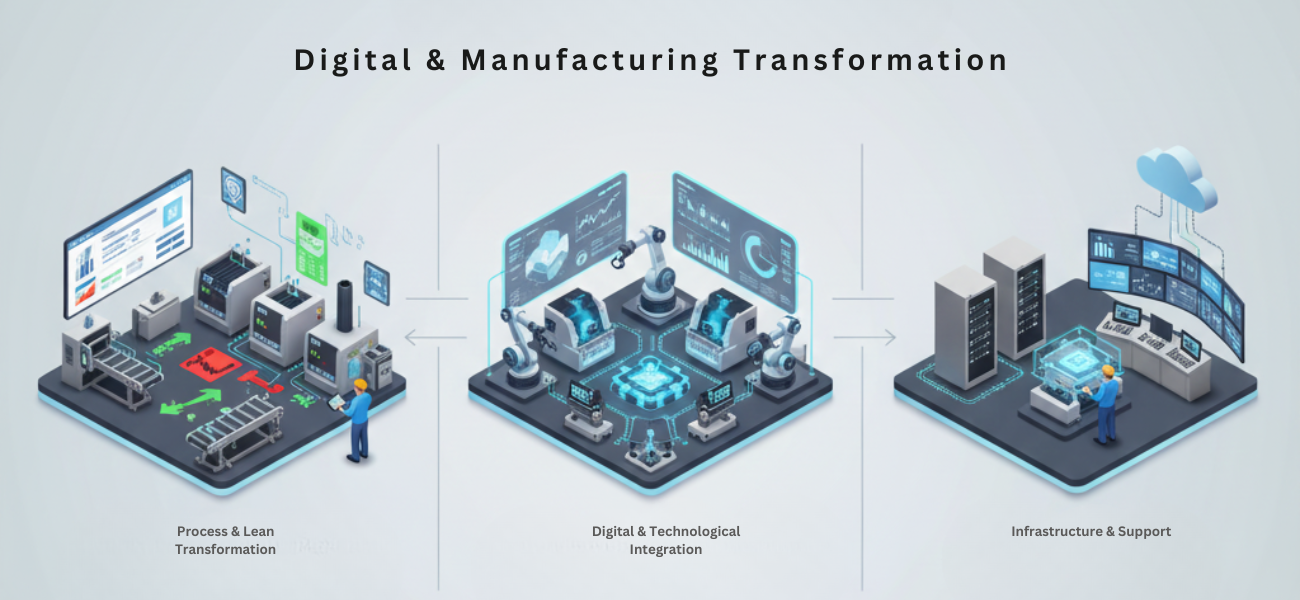

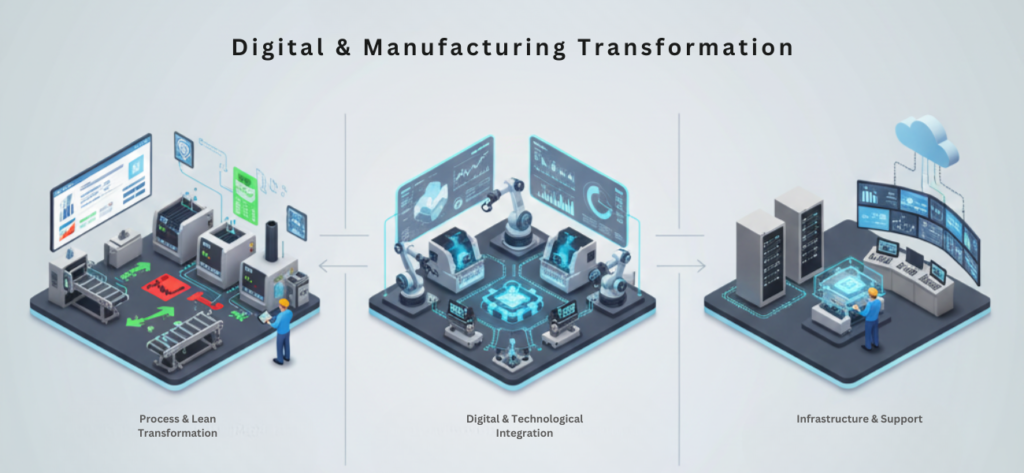

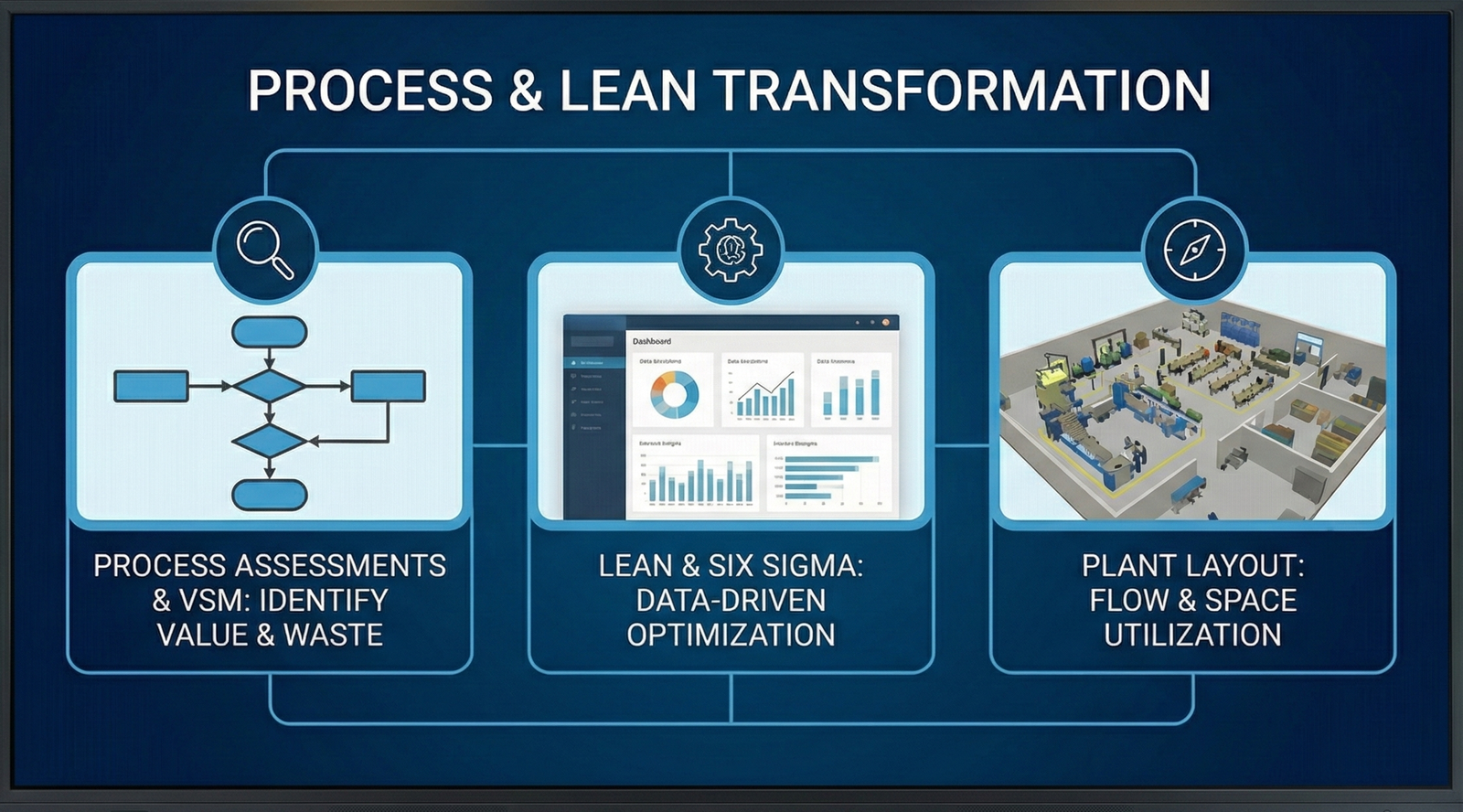

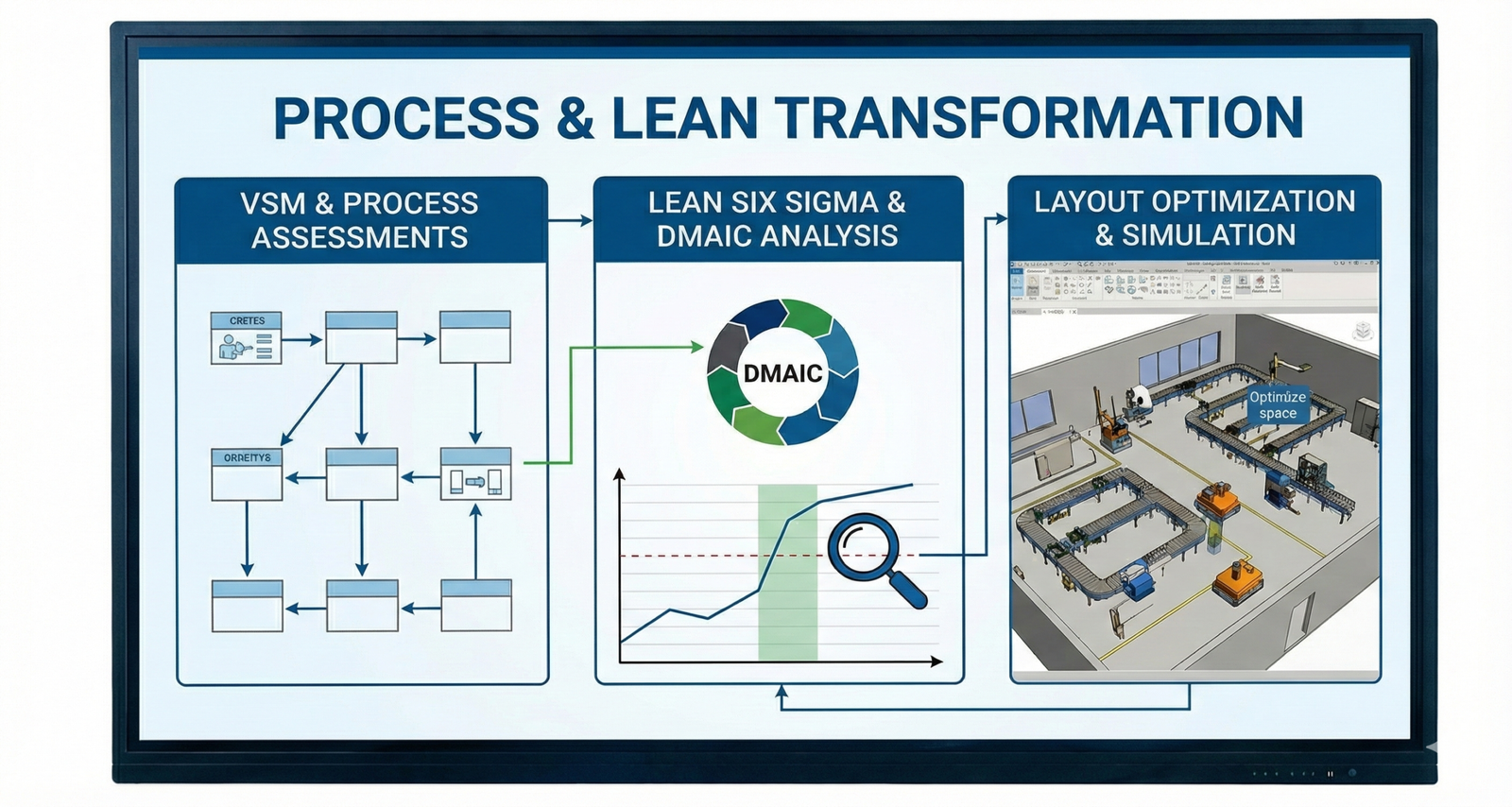

The foundation of a successful digital transformation lies in optimizing your existing processes. We help you eliminate waste and build a culture of continuous improvement.

Process Assessments & Value Stream Mapping (VSM)

We begin by conducting a thorough analysis of your current operations. Using Value Stream Mapping, we visually map your entire workflow to identify activities that create value and those that generate waste. This allows us to pinpoint bottlenecks, redundancies, and opportunities for improvement.

Lean & Six Sigma Gap Analysis

We employ rigorous, data-driven methodologies like Lean and Six Sigma to measure your process performance against industry benchmarks. This gap analysis helps identify the root causes of inefficiencies and defects. We then develop a targeted action plan using frameworks like DMAIC (Define, Measure, Analyse, Improve, Control) to drive significant improvements in quality and productivity.

Plant Layout Optimization & Simulation

An optimized plant layout is crucial for efficient workflow. We use advanced simulation software to model and test different layouts for your factory floor. This allows you to visualize material flow, reduce travel time, and maximize space utilization before investing in physical changes, minimizing disruption and ensuring optimal performance.