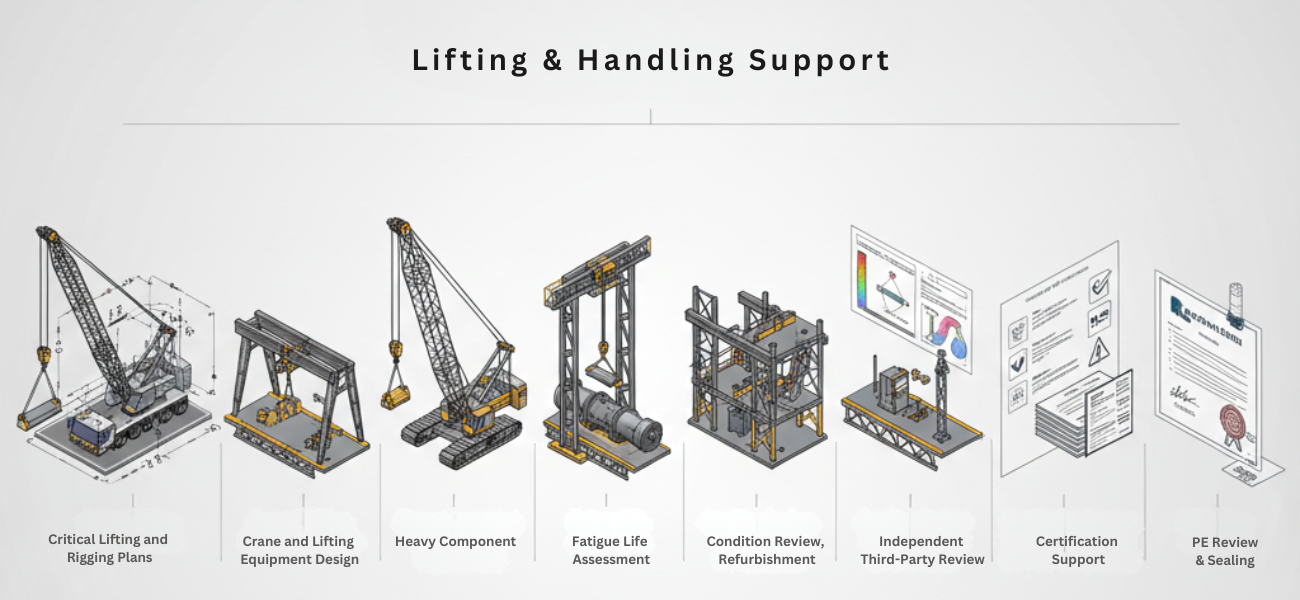

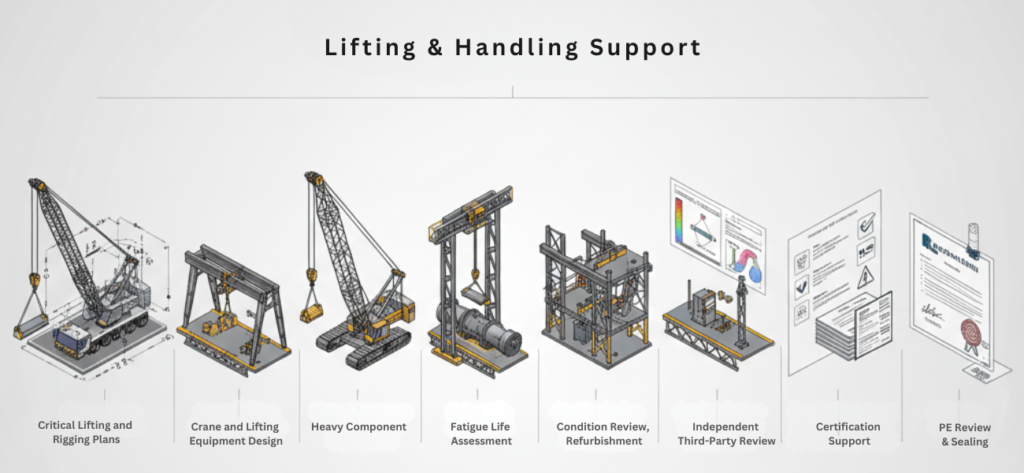

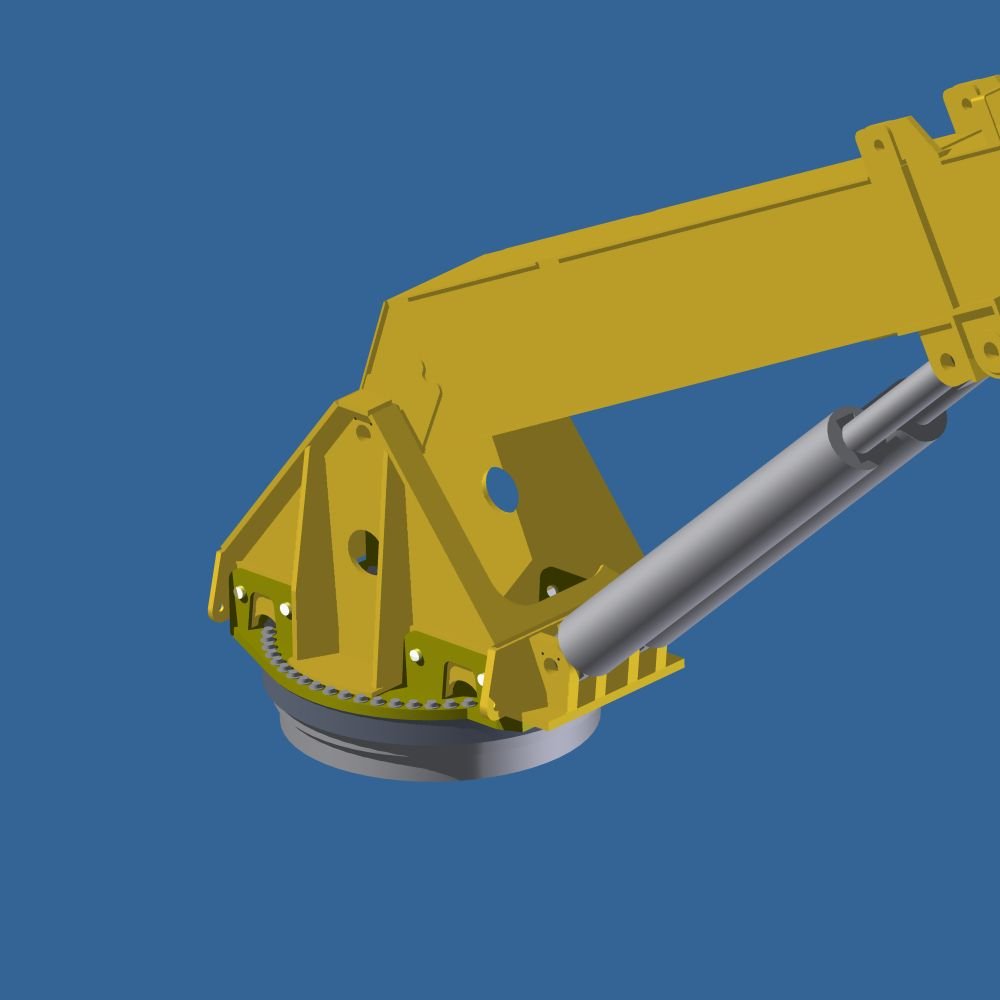

We provide specialized structural engineering services for lifting equipment and offshore crane systems, supporting safe and reliable performance in marine, offshore, and port environments. Our designs address the unique challenges of dynamic loading, fatigue, corrosion exposure, wind and wave effects, vessel motion, and demanding operational conditions.

Our approach integrates advanced structural analysis, lifecycle engineering, and standards-based compliance to develop robust and efficient designs suitable for both permanent and operational lifting systems. We support projects across fixed offshore platforms, floating units, and port and harbor facilities, ensuring designs are aligned with site-specific constraints and operational requirements.

Engineering evaluations consider strength, stability, fatigue life, dynamic response, and defined operating envelopes, as well as interfaces with supporting structures such as decks, pedestals, foundations, and supporting frames. Our work supports new designs, upgrades, re-ratings, and in-service evaluations, helping ensure long-term structural integrity and operational safety.

We provide integrated engineering support for API 2C compliance and third-party certification, helping manufacturers, owners, and operators navigate the requirements for design, manufacturing, testing, and operation of offshore and lifting equipment.

Our services bridge engineering design, fabrication practice, testing validation, and operational use, while coordinating with recognized certification and classification bodies such as ABS, DNV, BV, and LR. We support alignment of structural analysis, fatigue assessment, load testing evaluation, and operating limits with certification expectations.

Engineering involvement includes verification of design criteria, review of load cases and operating conditions, assessment of fatigue and stability, and support during certification review cycles, reducing approval risk and minimizing rework.

Standards & Code Alignment

Our lifting equipment and offshore crane designs are developed in alignment with applicable international codes, industry standards, and classification requirements, including:

- API 2C – Offshore Crane Design, Manufacturing, Testing & Operation

- ISO 19901 / ISO 4301 / ISO 8686 – Offshore and lifting equipment standards

- DNV Rules & Standards – Offshore lifting appliances and structural design

- ABS Rules – Offshore lifting devices and structural verification

- Bureau Veritas (BV) & Lloyd’s Register (LR) requirements

- Applicable ASCE, AISC, and project-specific specifications

Design assumptions, analysis methods, and acceptance criteria are aligned with the governing standard and certification pathway to support efficient approval and long-term compliance.